- 产品描述

-

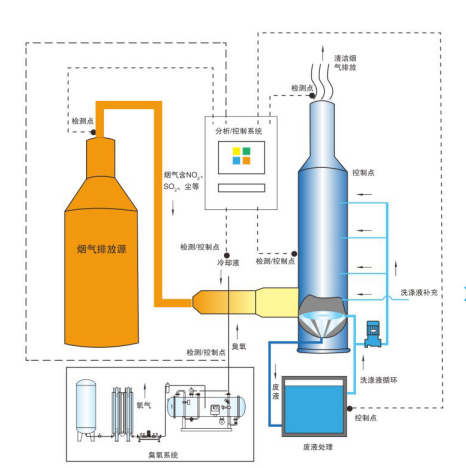

臭氧氧化脱销工艺

工作原理

在烟气温度100-200°C的工况下,利用臭氧和催化氧化装置将低价态.不溶于水的氮氧化物氧化成高价态.易溶于水的氮氧化物,再通过洗涤液喷淋吸收工艺将氮氧化物吸收掉。

when the flue gas temperature reaches 100-200°C,ozone and catalyticoxidation device make low state nitrogen oxide in the flue gas which isinsoluble in water to be oxidized into nitrogen oxide which is soluble inwater,and then nitrogen oxide will be adsorbed by alkaline washingprocess.适用领域

火电厂,热电厂、焦化厂,石油炼化厂、工业窑炉、工业锅炉、垃圾焚烧厂、生物质发电厂

Thermal power plant, power plant, coking plant, oil refinery, industrialfurnace,industrial boiler,waste incineration plant,biomass powerplant.技术特点

在烟气温度100-200°℃的工况下使用,不需增高烟气的温度,节约能源;

臭氧分解后变为氧气,无二次污染,不使用氨等还原剂,无氨逃逸问题;

在NOx含量和烟气量都不稳定进气条件下,维持90%以上的去除率;

不受烟气中粉尘影响,可以配合脱硫进行一体化洗涤,同时可脱除汞等重金属;

使用寿命长,脱硝系统设备按15年使用寿命设计,且工艺中无催化剂更换。

works under the condition of 100-200°C flue gas temperature withoutincreasing flue gas temperature to achieve energy conservation.

Ozone is decomposed into oxygen without second pollution;do not useammonia and other reducing agents to avoid ammonia escape problem.

Clearance rate is higher than 90% even if the NOx content and flue gasvolume are not stable.

lt is not influenced by dust in the flue gas. Ilt can be combined withdesulfurization to do integrated washing, while the heavy metal mercurycould also be removed.

Denitrification system life time is designed with 15years withoutreplacing catalyst.

产品咨询

在线留言